The Rise of Biomaterials

The fashion industry, one of the most polluting industries in the world, is slowly adopting sustainable practices starting with the use of biomaterials. Bio-based innovative materials developed by niche companies like Pyratex and Allbirds are now being used by retail giants such as Reebok, Timberland, Adidas and Hermes.

Those plant-based alternatives have an unfair advantage over their man-made counterparts: they can sequester CO2 instead of emitting it. But in the race to reduce carbon emissions, fashion is far from being the worst culprit. Building materials and construction account for 11% of greenhouse gas emissions and just three materials – concrete, steel, and aluminum – are responsible for 23% of total global emissions.

If there is one industry that needs systemic change to curb climate change it is the building industry, and re-evaluating the materials traditionally used in buildings is one of the most critical steps.

This means thinking beyond wood, which Mina Hasman (sustainability lead at HOM) described as “yesterday’s material”. Here are four natural materials that have the credentials to become mainstream architecture and design solutions in the next decade.

Hempcrete

Hempcrete or hemplime is a biocomposite material made from a mixture of hemp hurds (shives) and lime (from limestone), sand, or pozzolans, which is used as a material for construction and insulation. It is not as brittle as concrete so less prone to cracks and suitable for earthquake areas while being seven times lighter than concrete. It is ready to harvest in 14 weeks and can grow in any climate and soil condition making it an excellent solution to reclaim unusable land and rejuvenate poor soils. Each tonne of hemp cellulose produced absorbs up to 2 tonnes of carbon dioxide making it a valuable carbon sink. It is worth noting that hemp walls are not loadbearing but their acoustic and insulation credentials make it a sustainable option for non structural walls.

Pictured: Sativa Sanctuary – HempCrete house in Witchcliffe, WA

Bamboo Timber

Far from its original tubular shape, bamboo can now be engineered into timber-like products that outperform most hardwoods. With the tensile strength of steel and the compression strength of concrete, bamboo is a durable and sustainable alternative to timber. Contrary to most trees that require 20 to 30 years to mature, bamboo is ready to harvest in 5 to 7 years and produces 35% more oxygen and stores up to 4 times more carbon than trees. Because bamboo is technically a grass, it is not currently recognised as a solution for load bearing applications but everything cosmetic you need in timber can be made in bamboo, from cladding and flooring to fencing and shading.

Pictured: CityLife Shopping District by Zaha Hadid Architects in Milan – Engineered bamboo ceiling

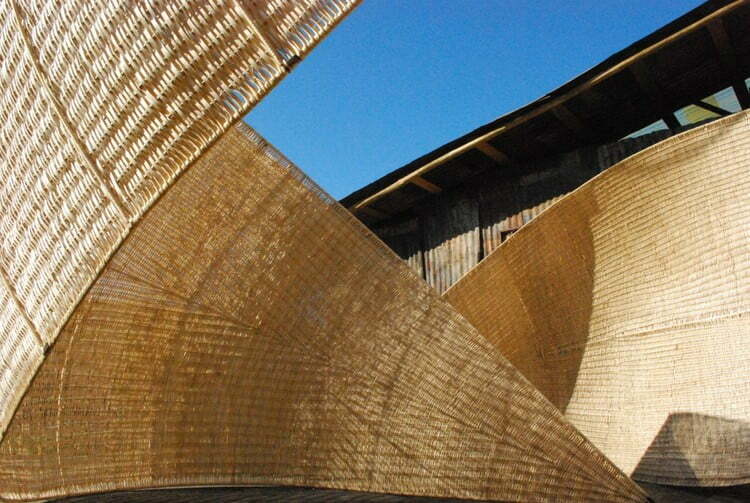

Rattan

Rattan has been a staple of interior design for decades but its sustainable credentials are often overlooked. Rattan is a naturally renewable palm that grows in the tropical regions of Africa, Asia and Australasia. The most unusual thing about rattan is the fact that it grows on other trees. It creeps up surrounding trees in order to reach the light. Not only does rattan need trees to grow, it cannot grow in monocultures, which means rattan production contributes to preserve biodiversity.

Pictured: Wicker Membranes by Andrea von Chrismar

Palm Timber

On the Yucatan Peninsula, Mexican architects RED Arquitectos built a screen wrapped house made almost entirely out of wood from surrounding coconut trees. Despite being naturally abundant in the area, palm timber is very rarely used for housing. Although Mexico is one of the world’s top coconut tree growing countries, the material is not available industrially and can only be sourced through artisans. Similarly to bamboo timber and hempcrete, palm timber is not (yet) suitable for loadbearing applications but using it for standalone structures such as fencing and screening alleviates the pressure put on global timber production.

“I believe that in the next couple of years, many brands won’t be able to keep using the materials they are using at the moment because there will be way more legislation,” says Regina Polanco, founder of bio-based textile manufacturer Pyratex. Regulations coupled with growing pressure from customers means specifiers have to make the switch sooner rather than later in order to familiarise themselves with the mainstream materials of tomorrow.

Biomaterials are a no brainer when it comes to construction: they reduce the overall carbon footprint, optimise the use of existing resources, restore biodiversity and enhance carbon sequestration. When these biomaterials become part of mainstream commercial use, it promises to dramatically change the image and most importantly, the impact of the built environment.

Sources:

https://architecture2030.org/why-the-building-sector/

https://www.dezeen.com/2021/12/28/biomaterials-review-2021/

https://www.dezeen.com/2022/03/08/red-arquitectos-casa-numa-coconut-palm-wood-architecture-mexico/